Tools

As requested by the flat glass processing industry the machines of new generation are operating at faster speeds. Also, the market demand for precision in processing quality and for higher machine production capacities for glass products is increasing every day.

Although manufacturers of glass processing machines are making great efforts to support glass processors using state-of-the-art technology, it is clear that, this can only be achieved by selecting the right machine-processing tool combinations. This means that the processing tools also need to keep

themselves up-to-date in terms of quality and speed. To ensure this, BENTELER Glass Processing Equipment is offering high quality tools to satisfy your customer needs. We are proud to serve worldwide leading glass processing companies with our tools.

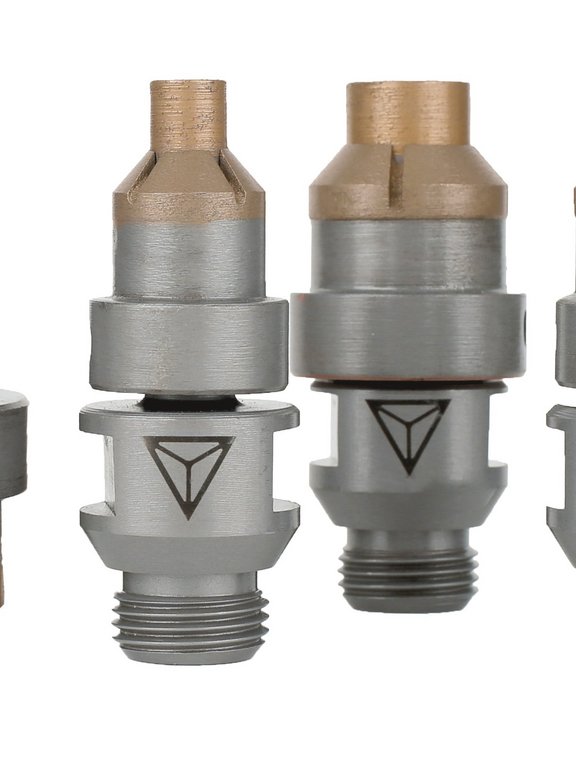

Standard drill and countersink

Drill

- Standard drilling bit

- coated body resistive for corrosion

- 75 mm length

Drill + Countersink

- Drill with adjustable countersink

- coated body resistive for corrosion

- 75 mm length

- segmented countersink

Countersink

- Coated body resistive for corrosion

- 75 mm length

- segmented countersink

- integrated water outlet holes

Special drill and countersink

- special formula for diamond mixture

- coated body resistive for corrosion

- 75 mm length

- Drill with adjustable countersink

- coated body resistive for corrosion

- 75 mm length

- segmented countersink

- Special formula for diamond mixture

- coated body resistive for corrosion

- 75 mm length

- Combined flat edge grinder and milling tool

- special formula for diamond mixture

- coated body resistive for corrosion

- short cycle times, integrated water outlet holes

- can be combined also with Pencil edge grinder

- Special formula for diamond mixture

- coated body resistive for corrosion

- Pencil edge / flat edge grinding tool

- integrated water outlet holes