Processing Center

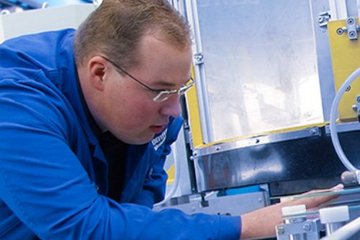

With the new CNC-Processing-Center, BENTELER moved an enormous step forward to support the production of shaped glass in the glass industry with short set-up times.

Processing Center

With the CNC processing center, BENTELER Glass Processing Equipment enables simple and fast production of custom glass with low setup times. Inline processing greatly simplifies the handling of large dimensions and eliminates the cumbersome, time-consuming setup process. The BENTELER processing center is highly versatile, thanks to a variety of different working widths.

Advantages

High precision:

- Laser measurement technology ensures positioning accuracy

- Automatic tool sharpening maintains consistently high edge quality

- Optimal drilling results with simultaneous drilling from both top and bottom

- Automatic removal of glass residues

Flexibility:

- No restrictions on the positioning of drill holes

- BENTELER Interface Management retrieves processing data directly from the CNC program during work preparation

Process security:

- Complete processing of flat glass at the highest level: Grinding, polishing, milling, and drilling on a single machine saves time and ensures product quality.

- Long lifespan and minimal maintenance due to easy accessibility and the use of high-quality machine components.

- Accurate glass measurement with a probe for precise detection.

Ease of Operation:

- Simplified glass handling through inline processing

- Secure glass hold with suction field

| Fields of application |

|---|

| Architectural Glass Automotive Glass Technical Glass |