Drilling

Machines

The BENTELER Drilling Machines for flat glass are suitable for all drilling and milling operations in single and serial production even for coated glass.

Glass Drilling Machines

Precision down to the finest detail: BENTELER Glass Processing Equipment's flat glass drilling machines are suitable for any drilling patterns and typical milling tasks in single or series production—optionally with water jet cutting for internal and external cuts. High repeat accuracy and minimal setup times ensure maximum flexibility and optimal cost-efficiency.

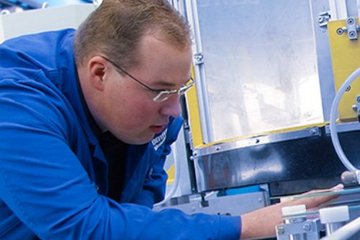

The BENTELER Portal Drilling Machine is a reliable process drilling machine and especially suitable for larger sizes of coated and uncoated glass. From one spindle pair up to max. two spindle pairs, the portal drilling machine covers all usual products. CNC-controlled axes and excellent repeatability guaranteed with minimal setup time for optimal cost efficiency and high flexibility.

Advantages

High precision:

- Dynamic CNC positioning of hole coordinates

- Automatic tool offset and calibration system

Flexibility:

- Two independent pairs of drilling spindles

- High performance milling spindle with speeds at 10000 min -1

- Automatic tool changer with 10 or 20 tool positions

Process reliability:

- Fully enclosed drilling spindle

- Separate milling spindle

- Modern CNC-operation

Simple operating:

- Easy user interface of hole pattern programming

- Fully automatic programs for drilling and countersinking

- Data input parallel to production

- Integration in customized software

| Technical data | Fields of application |

|---|---|

| Architectural Glass |

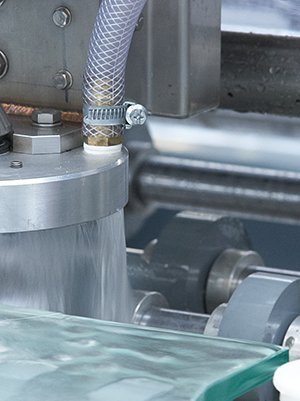

With this option inner and outer cuts can be produced in a short cycle time with high precision. The edge quality can be increased and the cutouts can be lined, due to an additional milling and seaming spindle.

Advantages

- variable cutting contours, no restrictions by tools

- compared with conventional milling: Process Factor 2.0

- automatic glass disposal of standard cutouts

- suitable for the processing of laminated glass

- water curtain for the protection of surrounding machine components

- controlled capture of the abrasive sand

- radiant energy is absorbed

- specific water flow in separate tanks

- high edge quality

seaming spindle for seaming / finishing

| Technical data | Fields of application |

|---|---|

| Architectural Glass Automotive Glass Technical Glass |

The BENTELER vertical drilling machine performs fast and precise in your drilling tasks. The drilling machine automatically changes tools in five different sizes. Additionally the machine offers a strong construction with corrosion resistant mechanical design and is suitable for flat and shaped glasses.

Advantages

fast and precise drilling perfomance

- suitable for flat and shaped glasses

Flexibility:

- can be used as a single machine or in combination with the vertical washing machine

Process reliability:

- automatically changing tools in five different sizes

- Front and Rear Spindles at the same time

- Drilling and Countersinking

- Drilling and Countersinking process can be done at the same time

Countersinking can be done from back and front side of the glass

| Technical data | Fields of application |

|---|---|

| Architectural Glass Technical Glass |

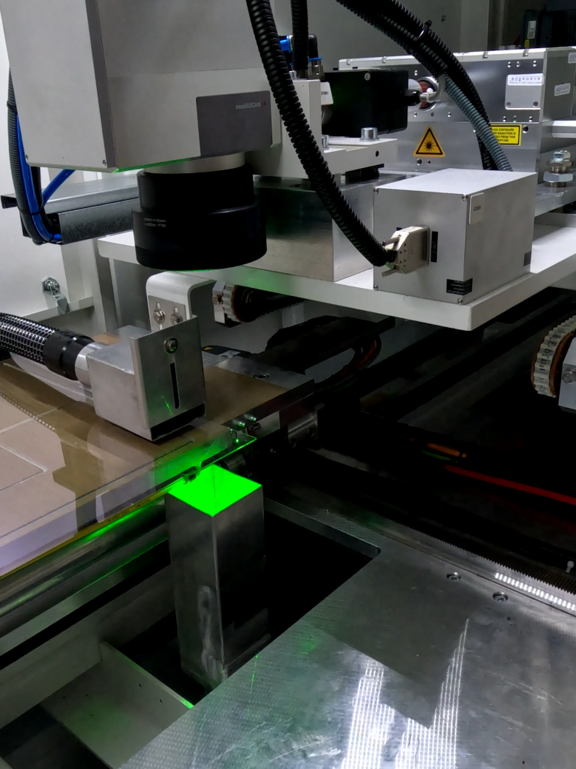

We integrate technical innovations into a complete line! The laser drilling machine from BENTELER Glass Processing Equipment not only convinces with the speed of the holes as well as the number and accuracy of the lasers. In addition, we offer an integrated complete package for fast process handling, including robot loading, washing machine and laser marking. All in one!